|

|

| ERGONOMICS | |

|

Atlas challenges the notion that you can't move heavy loads on smaller wheels. Our dual wheel casters easily negotiate common obstacles like door-jams, cracks, and grates and they perform better ergonomically than most casters with wheels twice the size. At high loads, moving heavy equipment on casters by hand can be very difficult. Compared to other industrial casters, our casters have several distinct advantages when it comes to ergonomics:

|

|

| Test Conditions | |

|

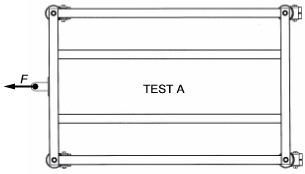

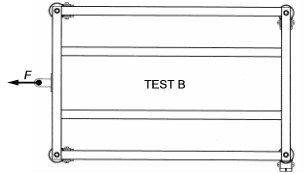

Apparatus: A steel frame with four Atlas Casters was evenly loaded with crates of solid steel material as shown in the picture above. The crate was weighed with a high resolution digital scale and additional weights were placed on top to vary the load. Test Conditions: All ergonomic tests were conducted on a level and dry concrete floor that was swept clear of any debris. The wheels used in testing were in a slightly used condition. Tests: Two tests were performed to compare the ergonomic performance of the various wheel/ bearing combinations. Test A recorded the maximum pull force required to move the cart with all casters in alignment. Test B performed the same measurement with the two rear wheels cocked at a 90º angle. Each test was conducted at least eight times with less than a minute between each move. The results were averaged and presented with the standard deviation of the data, i.e., the average uncertainty in the measurement. |

|

| 500 Series Test Results | |

| WHEEL MTRL | WHEEL BRG | CODE | TEST | 1000 LBS | 1500 LBS | 2000 LBS | |

|---|---|---|---|---|---|---|---|

| Phenolic | Plain | PHN | A | 20 ± 1.6 | 32 ± 2.9 | 43 ± 1.8 | |

| B | 23 ± 2.6 | 33 ± 1.6 | 44 ± 2.5 | ||||

| Polyurethane 75D | Delrin | PXD | A | 33 ± 2.0 | 52 ± 3.2 | 68 ± 3.9 | |

| B | 41 ± 1.8 | 63 ± 2.6 | 89 ± 4.3 | ||||

| Polyurethane 75D | Precision | PXP | A | 9 ± 1.3 | 13 ± 2.9 | 18 ± 2.3 | |

| B | 34 ± 1.2 | 50 ± 2.2 | 67 ± 4.7 |

| 1000 Series Test Results |

| WHEEL MTRL | WHEEL BRG | CODE | TEST | 2000 LBS | 2500 LBS | 3000 LBS | 3500 LBS | 4000 LBS |

|---|---|---|---|---|---|---|---|---|

| Phenolic | Plain | PHN | A | 40 ± 4.4 | 49 ± 3.3 | 73 ± 3.5 | - - | - - |

| B | 35 ± 3.6 | 47 ± 4.1 | 62 ± 2.0 | - - | - - | |||

| Polyurethane 75D | Delrin | PXD | A | 64 ± 3.5 | 96 ± 5.3 | 108 ± 2.1 | 130 ± 5.0 | - - |

| B | 87 ± 3.3 | 102 ± 3.1 | 108 ± 3.2 | 151 ± 9.8 | - - | |||

| Polyurethane 75D | Precision | PXP | A | 18 ± 2.4 | 39 ± 2.9 | 48 ± 4.7 | 64 ± 5.3 | 79 ± 5.3 |

| B | 60 ± 2.4 | 65 ± 4.3 | 85 ± 5.6 | 100 ± 5.8 | 124 ± 6.2 |

| NOTES |

|